How to Choose the Right Manufacturing Partner in Shenzhen

Selecting the ideal manufacturing partner is a pivotal step in hardware development, especially when collaborating across continents. At HW Lab, we navigate this challenge daily, with myself spearheading software development from Japan and my co-founder Pedro managing hardware initiatives from Argentina. Our recent journey in choosing reliable partners in Shenzhen for our WebScreen prototypes was both instructive and rewarding. In this article, we'll share how we navigated the selection process, analyzed various quotations, and ultimately identified the best partners for our project.

Why Shenzhen?

Dubbed the "Silicon Valley of Hardware," Shenzhen stands out as a global hub for electronics manufacturing. The city boasts a rich ecosystem of suppliers specializing in electronic components, making it an ideal destination for sourcing materials and manufacturing prototypes. Competitive pricing, rapid turnaround times, and access to a vast array of components have solidified Shenzhen as our preferred location for hardware development.

1. Initial Supplier Outreach: Establishing Communication

Our process began by reaching out to multiple suppliers to assess their capabilities and responsiveness. Initial communications were crucial in understanding their ability to meet our specific requirements. Our main criteria included:

Responsiveness and Clarity: Efficient and clear communication is essential for smooth collaboration. Suppliers who responded promptly and provided transparent answers to our inquiries made a strong first impression.

Technical Capabilities: We required suppliers proficient in handling complex PCB requirements, such as resin-filled vias and strict adherence to provided Gerber files.

2. Comparing Quotations: Beyond Just Price

Upon receiving multiple quotations, we recognized the importance of looking beyond mere pricing. Our considerations included:

Pricing Analysis: We compared costs across different quantities, both with and without assembly services. Discounts and additional services offered were also factored into our evaluation.

Quality of Communication: Some suppliers, despite competitive pricing, lacked clarity or failed to provide comprehensive information—a potential red flag.

Flexibility and Customization: We valued partners willing to accommodate custom requests and make necessary adjustments with minimal back-and-forth.

Through this comparison, two suppliers distinguished themselves by offering competitive pricing and demonstrating a thorough understanding of our technical requirements:

Supplier A: Provided a competitive quote coupled with excellent communication. Their proactive approach included offering a discounted price unprompted, highlighting a customer-first mindset.

Supplier B: Although their pricing was slightly higher, they were meticulous in their responses and proactive in suggesting design improvements, making them a valuable partner for ensuring quality.

3. Evaluating Work Processes: Proactivity and Support

Assessing the suppliers' work processes involved examining their support systems, proactivity, and overall operational procedures. Notable observations included:

Support and Updates: Supplier A consistently updated us at every production stage and promptly addressed any issues. They proactively identified potential design problems, allowing us to implement corrections before production commenced.

Proactivity: Supplier B swiftly pinpointed issues within our Gerber files and recommended solutions, helping us avoid costly production mistakes.

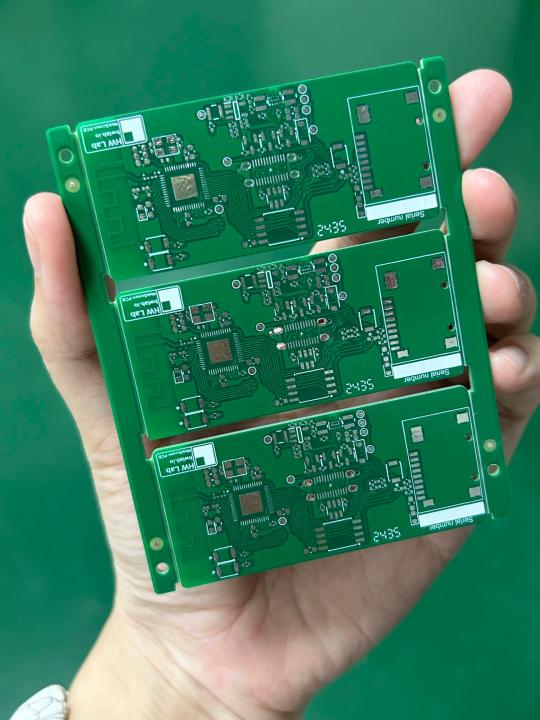

Quality of the Final Product: While both suppliers delivered high-quality PCBs, Supplier A's proactive communication regarding issues gave them a competitive edge.

4. Making the Final Decision: Building Long-Term Relationships

After thorough analysis, we decided to engage both suppliers for different facets of our prototyping process, leveraging their unique strengths:

Supplier A: Chosen for their exceptional communication and competitive pricing for smaller production batches.

Supplier B: Selected for their attention to detail and willingness to provide constructive design feedback, making them ideal for more complex prototype iterations.

5. Lessons Learned: Key Takeaways for Choosing a Manufacturing Partner

Our experience yielded valuable insights that may benefit others embarking on a similar journey:

Prioritize Communication: Responsive suppliers can save time and resources by promptly addressing issues early in the process.

Look Beyond Price: Assess the quality of service, flexibility, and the supplier's willingness to go the extra mile.

Value Proactivity: Suppliers who actively identify potential issues and suggest improvements can be invaluable long-term partners.

Build Relationships: Fostering strong relationships can lead to enhanced service and support in future projects. It's important to think beyond the current order and consider long-term collaboration.

6. What’s Next?

We are enthusiastic about continuing our journey with these partners and are eager to refine our product through subsequent iterations. Moving forward, our goal is to maintain and strengthen these relationships, continuing to innovate with the support of our trusted manufacturing partners in Shenzhen.

By sharing our experiences, we hope to provide guidance to others in the hardware development community. Choosing the right manufacturing partner is a nuanced process that goes beyond cost analysis; it involves evaluating communication, technical capabilities, and the potential for long-term collaboration. With the right partners, the complex journey of hardware prototyping becomes a collaborative and rewarding endeavor.