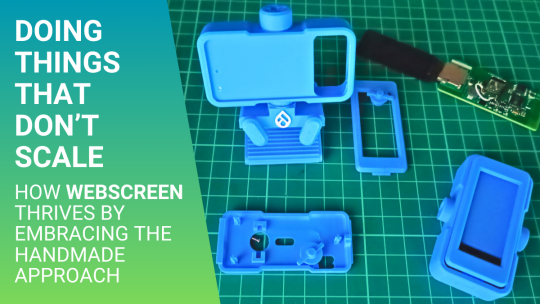

Doing Things That Don’t Scale: How WebScreen Thrives by Embracing the Handmade Approach

We’ve all heard that startups must “do things that don’t scale.” It sounds counter-intuitive in a world dominated by mass production and massive distribution, but as Paul Graham highlighted in his YC essay, big things often start with small, hands-on efforts. At WebScreen, our open source hardware project, we’re taking that very path.

Manufacturing Constraints: The Hardware Dilemma

Unlike software companies, hardware startups face a unique catch-22. As the Y Combinator blog post explains:

“Hardware startups face an obstacle that software startups don't. The minimum order for a factory production run is usually several hundred thousand dollars. Which can put you in a catch-22: without a product you can't generate the growth you need to raise the money to manufacture your product… Like paying excessive attention to early customers, fabricating things yourself turns out to be valuable for hardware startups. You can tweak the design faster when you're the factory, and you learn things you'd never have known otherwise.”

That’s precisely the route we’re following at WebScreen. Pulling a “Meraki,” we’re manufacturing the first few batches by hand, assembling and adjusting every device ourselves. It’s time-consuming, but we can rapidly iterate and gather authentic feedback—advantages that large companies with rigid production pipelines simply can’t match.

Embracing Personalization in Early Batches

Working with small runs means each device can be customized based on direct feedback from the community. We chat openly with our earliest users, gathering insights about design preferences, expansions, and repairs. We’re willing to do the dirty work of hands-on assembly because it helps us hone in on the details—just like Pebble did when they first sourced their own parts and discovered how critical “good screws” can be.

Faster Iteration & Community Engagement

By distributing prototypes instead of a final, mass-produced product, we give our early adopters a real voice in shaping WebScreen’s roadmap. Ideas move from suggestion to device prototype within days rather than months. This hands-on loop also builds a culture of respect for right to repair, ensuring everyone can keep their WebScreen running for years.

Standing Apart from Big Corporations

Our approach gives us an edge that big corporations struggle to replicate. Each unit is built with personal care, user-driven insights, and quick experimental tweaks. We’re not weighed down by layers of internal approval, so we can move faster—building real trust with a community that wants to see open source hardware done right.

Looking Ahead: Our Upcoming CrowdSupply Campaign

While these prototypes aren’t yet ready for factory-scale runs, we’re gearing up for a CrowdSupply campaign. By subscribing, you’ll get early access, sneak peeks at new features, and first dibs on any upcoming batch releases. Your feedback and support will help us grow WebScreen into a fully formed open hardware ecosystem—always centered on its community.

Support Us on Crowd Supply

We’re on Crowd Supply, and we need your help to bring WebScreen to more people. Your backing makes it possible to keep prices low and quality high—so everyone can enjoy the power of an open-source secondary display.

Check out the campaign and get involved: WebScreen on Crowd Supply