How 3D Printing Accelerates Prototyping for WebScreen and Other Innovations at HW Lab

At HW Lab, 3D printing has become a game-changer in how we approach prototyping. Whether it's for our latest innovation, WebScreen, or other projects, the Bambu Lab P1P 3D printer has proven to be an essential tool, allowing us to quickly iterate and refine our designs.

Why 3D Printing? 3D printing has transformed product development by enabling rapid prototyping and significantly reducing the time to market. Unlike traditional methods, which require expensive tooling and long lead times, 3D printing allows us to move from a digital design to a physical prototype in just a few hours. This speed and flexibility are crucial in today’s fast-paced tech environment, where innovation and quick iteration are key to staying ahead.

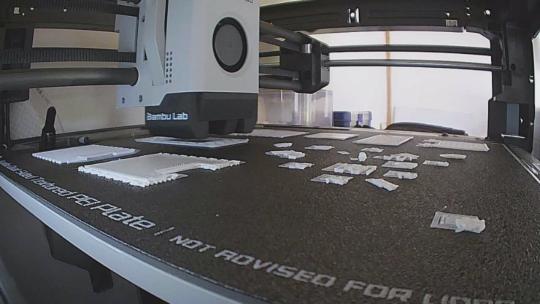

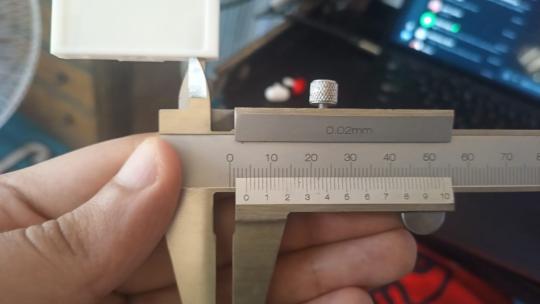

How We Use the Bambu Lab P1P The Bambu Lab P1P 3D printer is ideal for creating prototypes with complex geometries and intricate details. For WebScreen, we've leveraged the P1P to produce multiple iterations of our enclosures, ensuring the final product meets both functional and aesthetic requirements. Being able to print parts in-house allows us to test and refine designs rapidly, addressing potential issues early in the development process.

Partnership with Convert Studios To enhance our design capabilities, we've partnered with Convert Studios, an industrial design agency that excels in merging aesthetics with functionality. This collaboration has been instrumental in ensuring that our designs are not only visually appealing but also optimized for production. Convert Studios brings a wealth of expertise in industrial design, helping us to take our prototypes from concept to reality with precision and style.

Real-World Impact 3D printing has accelerated the prototyping process for WebScreen, reducing development time and costs. This technology also allows us to experiment with different materials and finishes, ensuring that the final product is both innovative and market-ready. The flexibility of 3D printing means we can easily incorporate feedback and make adjustments without the need for costly retooling, giving us a significant edge in product development.

What’s Next? As we continue to develop WebScreen and other products, 3D printing will remain a cornerstone of our prototyping process. We're also exploring new materials and applications for 3D printing, pushing the boundaries of what’s possible in product design and development. Stay tuned for more updates on how we’re using this transformative technology to bring innovative solutions to life.