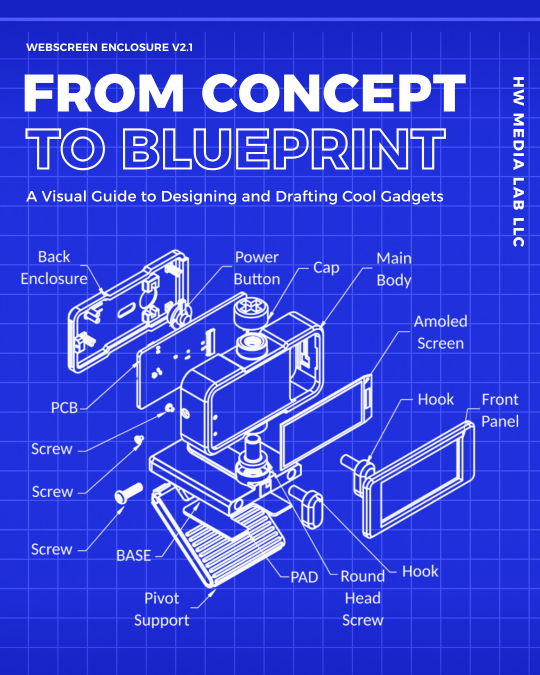

From Concept to Blueprint: A Visual Guide to Designing and Drafting Cool Gadgets

Bringing an idea to life isn’t just about inspiration—it’s about execution. At HW Lab, we’ve been on a mission to design WebScreen, a compact, secondary display that seamlessly attaches to your monitor, keeping you informed without breaking your focus. But turning this vision into a manufacturable product required expertise beyond our own. That’s where Convert Studios, an Australian design powerhouse, came in.

This post is a behind-the-scenes look at how we collaborated to take WebScreen from a concept to a fully engineered blueprint, ready for production.

The Vision: A Smart, Versatile Display

The concept for WebScreen was clear from the start:

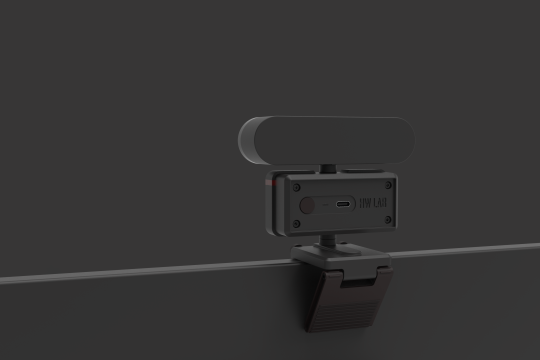

🔹 A sleek, compact gadget that attaches to monitors like a webcam

🔹 Customizable with JavaScript-based apps

🔹 Perfect for notifications, reminders, and real-time data

🔹 Hackable and open-source

But having an idea is one thing—making it manufacturable is another. That’s where Convert Studios stepped in.

Partnering with Convert Studios

Founded in 2008, Convert Studios specializes in industrial design, engineering, and product development. They’ve worked with brands like Cisco, Herman Miller, and BHP, but they also thrive on helping startups turn prototypes into reality.

With their expertise in enclosure design, 3D modeling, and production readiness, they helped us refine WebScreen’s form factor, ensuring that it’s both stylish and functional.

🔸 Precision Engineering – Ensuring WebScreen fits snugly on different monitors

🔸 3D-Printed Prototypes – Rapid iteration to get the best design

🔸 Scalable Manufacturing – Optimizing for mass production

The Design Process

Every great product goes through multiple design iterations. Here’s a quick breakdown of how we worked with Convert Studios:

🔹 Concept Sketching – Initial drawings to outline features and usability

🔹 3D Modeling – Creating CAD files for detailed analysis

🔹 Prototype Printing – Testing fit, ergonomics, and assembly

🔹 Material Selection – Choosing the best materials for durability and affordability

🔹 Manufacturing Readiness – Preparing the final blueprint for large-scale production

Engineering Challenges and Solutions

Like any hardware project, WebScreen had its fair share of challenges:

🔸 Mounting Stability – We tested multiple clip and hinge designs to ensure WebScreen stays in place.

🔸 Heat Dissipation – Optimizing the enclosure design to prevent overheating.

🔸 Component Accessibility – Making sure internal parts can be easily assembled and replaced.

With Convert Studios’ help, we overcame these hurdles and finalized a production-ready design.

Bringing WebScreen to Market

Now that WebScreen is fully designed and tested, the next step is bringing it to the world! We’re launching it via Crowd Supply, where you can support the project and help us make it a reality.

Join the campaign here: WebScreen on Crowd Supply

Your support helps us manufacture WebScreen at scale, reducing costs and making it accessible to more users.